2. Cardinal Health General Lab Supplies. To order, call: 800.964.5227 THERMO FISHER SCIENTIFIC - Verify the sterility of your instruments, vials, media ...

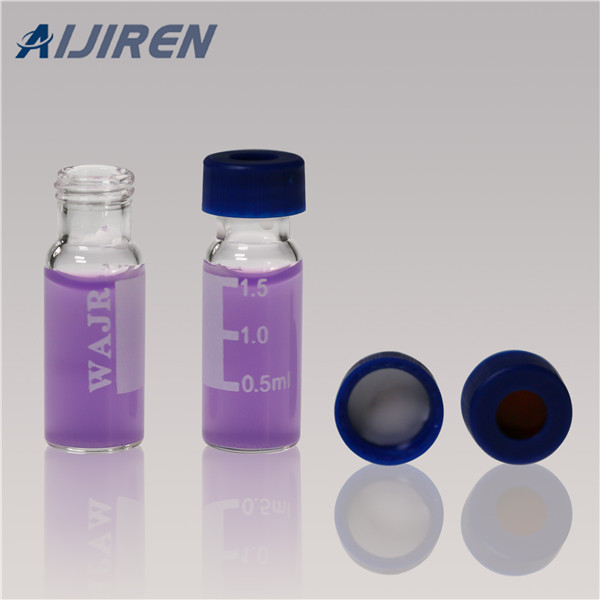

While maintaining the standard outer dimensions the internal volumes of these vials range from below 300µL to 2mL. Made of superior quality 33 expansion

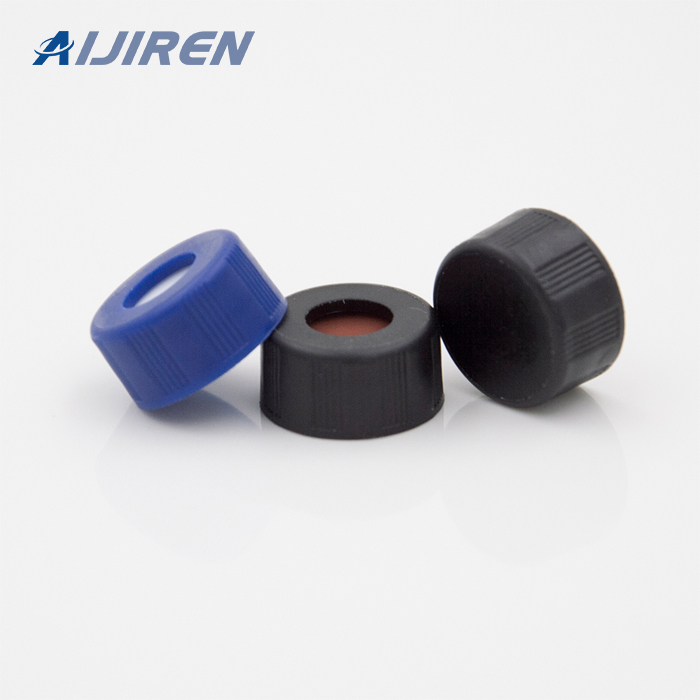

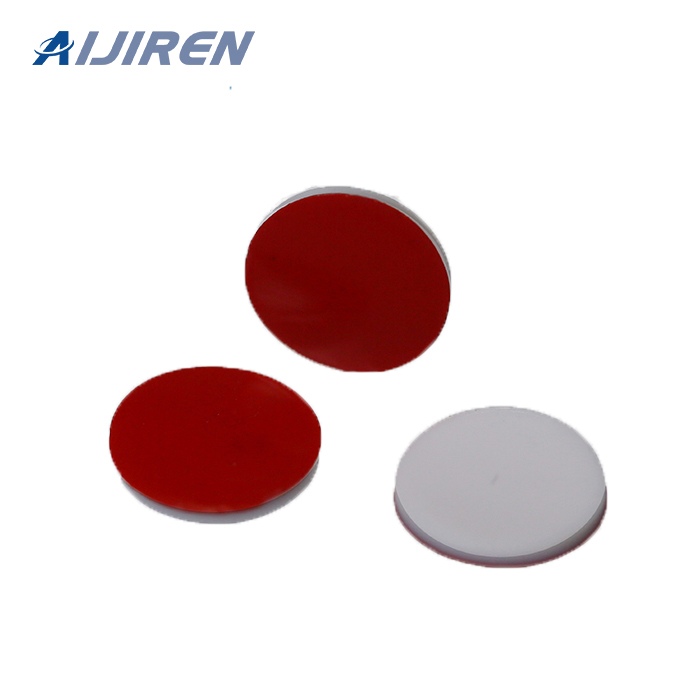

These 9mm wide-opening vials are built so that closures nearly eliminate septa push-through and have a stop point for consistent tightness and optimal seal

5 mL microtubes in the Eppendorf ThermoMixer® C · 5 mL Eppendorf microtube®, open · 5 mL microtubes - screw cap, snap cap and amber.

2ml standard opening screw top vials and caps (8-425). Vials. THC11090210 Vial screw top 2mL standard opening clear glass, no markings 100.

Thermo Fisher Scientific Inc. in the United States. Laboratory Requirements . ... hold standard sample vials and microtiter plates, and a built-in ...

Volume (mL)1.8 · Tube MaterialPolypropylene · Tube Bottom ShapeRound · Cap TypeScrew-Thread · Cap colorNatural · ThreadInternal · SterileYes · Height (in)1 57/64

to meet the high standards you have come to expect from Did you know: 2 mL high-recovery screw-top vials can be used with all autosamplers.

Vial Part: AR0-3910-13 Verex™ Vial, 9mm Screw Top, 2mL, Clear 33, w/ Patch, 1000/Pk.

supplier for laboratory Thermo Scientific HyperSep SPE will give consistently high ... Standard opening crimp top vials are compatible with all 11mm.

Our vials are manufactured from Type I Borosilicate Glass, which meets all USP, JP, and EP Pharmacopeia requirements. The glass performs excellent at high

Type: Autosampler Vial Vial Volume (Metric): 2mL Color: Blue Height (Metric): 32mm Diameter (Metric) Outside: 12mm Capacity (Metric): 2.0mL Vial Closure

About 8mm (8-425) standard opening screw vials · 2mL, 12x32mm standard opening vials · 8-425 thread finish · Smaller opening (5mm ID) has less solvent contact with

Thermo Scientific™ 9mm Wide Opening Amber Glass Screw MS Certified Vial Convenience Kits are fully lot-tested by multiple methods for 15 critical parameters

However, up to 40% of manufactured multilayer films go unused in the final packaging application because of inefficiencies in the packaging fabrication